Loading...

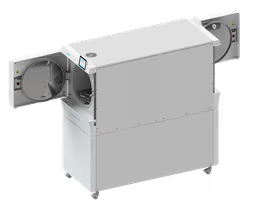

600 - 1,400 Litre SQUARE MAX Autoclave

Brand

- Astell Scientific

Model

- SVS600 , SVS875 , SVS1050 , SVS1200 , SVS1400

Manufacturing Country

- United Kingdom

Quality Certificates

ISO 17025

ISO 9001

Specification

Model:SVS600 (600 litres)

Model:SVS875 (875 litres)

Model:SVS1050 (1050 litres)

Model:SVS1200 (1200 litres)

Model:SVS1400 (1400 litres)

The 600 - 1,400 litre SQUARE MAX Autoclave Range is capable of sterilizing almost anything (additional options may be required) and easily customizable and with a range of different chamber sizes. The SQUARE MAX range is ideal for high throughput situations or bulky and awkward loads.

Astell Scientific offer a comprehensive standard range of square section autoclave chamber sizes, each one designed and manufactured with precision and care. During and after manufacturer all pressure vessels are stage inspected, hydraulically tested and stamped by a notified body. Astell pressure vessels are manufactured to PED, ASME U standards and carry numerous approvals for many other countries.

Standard SQUARE pressure vessel sizes:

400x400mm

500x500mm

600x600mm

700x700mm

with depths from 500mm to 2000mm

Astell also have the ability to manufacture pressure vessels to meet customer requirements – a great advantage over many other autoclave manufacturers. Contact us for details.

Autoclave pressure vessels are available in polished, electro-polished or bead blast chamber finishes, with each designed to ensure the base of the chamber creates a positive path to the drain for condensate. All components in contact with steam are manufactured from 316 stainless steel (other materials can be used on request), and as standard all connections are screwed, but pressure vessels with welded Tri-clover fittings to accept sanitary fittings can be accommodated should the customer require this. Finally, all Astell pressure vessels are fitted with bosses to accept rails for loading equipment and/or a standard base shelf.

Where a jacketed chamber is necessary, for the provision of superior drying for example (i.e. sterilizing wrapped instruments or fabrics), Astell pressure vessels are fully jacketed (not sectional as with some manufacturers) providing the best heat distribution and maximum surface area for quick and efficient cooling. Jacketed pressure vessels are designed to ensure full drainage after a cooling cycle to reduce water hammer.

Depending on load and sterilization requirements the addition of a

Heated Jacket:

Typical loads where a jacket would be required for drying include wrapped instruments or porous fabrics. Heated jackets are available on all Astell autoclaves over 95 litres with integral steam generators or with a direct steam supply. They add a secondary external layer to the autoclave allowing steam to circulate outside the sterilization chamber whilst insulating the main vessel. When a jacket is fitted, its effect is two-fold.

Firstly, when sterilizing fabrics and porous loads, the jacket is kept constantly heated which means that the chamber maintains a residual temperature between cycles, avoiding excessive condensate forming inside the chamber and wetting the load when steam enters the vessel. Secondly, after preventing condensation forming at the beginning of a cycle, at the end of a cycle the jacket stays running during a final vacuum, which then evaporates any remaining liquid, allowing porous loads to be touch dry when they are removed at the end of the cycle.

Vacuum facility :

AVC001 - ADVANCED 'PULSAR' VACUUM

Suitable for all units with an integral steam generator (or external steam supply), the AVC001 vacuum option is Astell’s most advanced method of air removal. It’s ideal for sterilizing porous materials and other loads where air pockets could easily form. An AVC001 vacuum cycle starts with a pre vacuum which is followed by negative and positive pulsing. By introducing steam between vacuum pulses, air is forced out of the autoclave chamber under pressure; the best method for removing air from porous loads and discard waste. Following the sterilization stage, a post vacuum removes the steam from the chamber. In combination with the jacket option, a drying stage then begins to ensure loads are touch dry upon removal.

AVC002 - PRE AND POST ‘SIMPLE’ VACUUM:

The AVC002 option is Astell’s basic vacuum system and is only suitable for standard autoclaves with the heaters in the chamber, or direct steam models (see Direct steam models). The cycle begins with a pre vacuum, reducing the chamber pressure and removing the majority of air. A free steaming/ air purge stage then begins. After the sterilizing stage is complete, water in the bottom of the chamber is expelled and then a post vacuum takes place, removing any remaining steam from the chamber and cooling the load. Please note: the AVC002 is a simple vacuum and as such does not have the drying capability of the AVC001 & Jacket option. or Cooling system may be required or recommended.

This range can also form the basis of a double door or pass-though autoclave if required.

Double ended or pass-through autoclaves are a special type of steam sterilizer typically used in high-containment laboratories dealing with dangerous pathogens and microorganisms, where a containment area and/or ‘clean room’ are completely separated. Facilities of this nature are usually categorised under four Biosafety levels, the lowest being BSL-1 and the highest BSL-4.

Because a pass-through autoclave needs to be accessed from both sides it may also be referred to as a double door autoclave depending on its final design, installation and operation.

At Astell, we have the experience to design and manufacture custom autoclaves, as our Barts Cancer institute case study proves, and we can confidently meet the most challenging design specifications and customer application requirements. One such example is the Biosafety designed pass-through autoclave (pictured top left), which in this case is interfaced to a Class III BSC/Glovebox.

This custom large capacity autoclave had to meet the high containment design requirements specified by the architectural engineering firm building the facility, whilst meeting the functionality requested by the end users.

In consultation, Astell paid particular attention to water consumption, effluent decontamination and facilities integration, whilst considering practicalities such as direction of workflow, servicing access requirements, validation and installation, all of which were addressed prior to manufacture of this double ended square section autoclave.

As with our other autoclaves, Astell provide a selection of options to ensure your double ended pass-through autoclave operates efficiently for its chosen application. These may include such things as stainless steel pipework, a stand-alone steam generator, automatic vertical or sideways opening doors, or a customized loading system using a trolley or truck for large or heavy items.

Another key requirement for the double door autoclave is the use of SPF (Specific Pathogen Free) seals, which ensures there is no risk of cross-contamination between the sterile and non-sterile areas of operation. In addition, Astell autoclaves can be supplied with systems to ensure ‘effluent retention’ and ‘exhaust filtration’ to meet the requirements of BSL-3.

The SQUARE MAX Range comes in capacities from 600 to 1,400 litres and is capable of sterilizing various items as standard and is upgradable to sterilize almost anything. Models are available in 600, 875, 1050, 1200 and 1400 litres. A steam generator is fitted as standard, however direct steam models are also available at no extra cost.

The standard unit is capable of sterilizing a wide variety of items or with additional options can be upgraded to offer wider versatility.

Features:

-316 stainless steel electropolished chamber

-Automatic sideways opening door operation

-Calibration and Validation available

-FDA 21 CFR part 11 software option available

-Cooling Lock

-External pressure guage

-Five password levels to stop lower level users making changes

-Full Range of Options & Accessories

-Integrated high capacity Steam Generator

-Optimised for low water and power consumption

-Optional Stainless Steel Panelwork

-Over Temperature Protection

-Standard Astell safety features

-Timed/Pulsed Free Steaming

-Fully programmable 5.7" Colour Touch Screen controller

-USB interface for downloading controller data

-Validation Port

Similar Products

You might also be interested in these products