Loading...

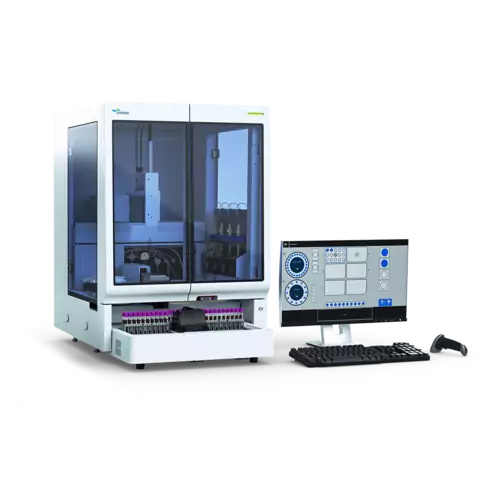

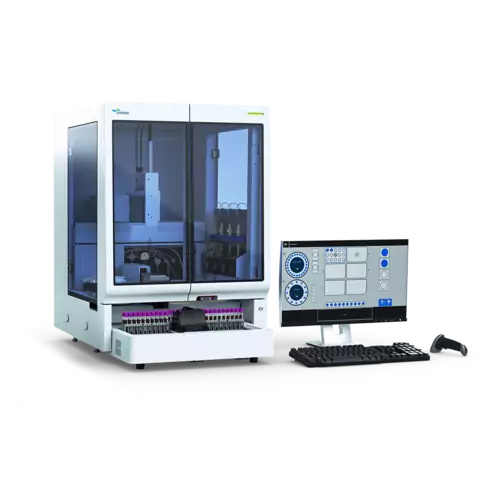

Automated sample preparation for clinical flow cytometry

Brand

- SYSMEX CORPORATION

Model

- PS-10

Manufacturing Country

- Japan

Quality Certificates

CE MARKING

FDA 510(k)

ISO 13485

Specification

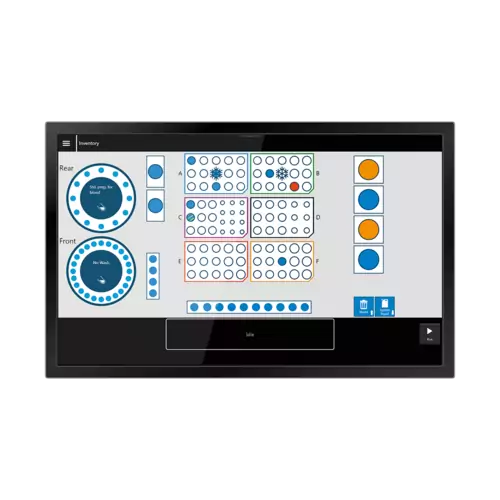

PS-10 Automated sample preparation for clinical flow cytometry

Flexibly and intelligently automates preparation of samples for flow cytometric analysis

Freely programmable to adapt to your individual needs, for both routine and complex applications

Improves confidence in the results, through the reduction of human handling errors

Provides traceability of samples, reagents and processing steps

The PS-10 is Sysmex’s response to the increasing demands and declining resources that today’s clinical flow cytometry laboratories are facing. This new sample preparation system offers an intelligent automation solution that delivers increased efficiency and flexibility for complex and routine flow cytometry applications.

Thoughtful automation for a new level of workflow efficiency.

*Technical Specifications :

-User-programmable procedures : lyse no-wash, lyse-wash, pre-lyse (bulk), intracellular staining and custom sequences / variables: sample volume, antibody volumes, cocktail volume, lyse volumes, buffer volumes, incubation times

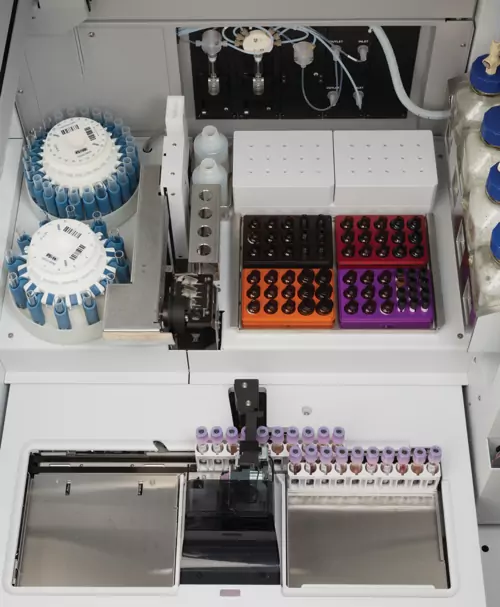

-Sample and reagent volume ranges sample: 50 μL or 100 μL in fixed volume mode or threshold mode; 20 μL – 100 μL in variable mode, adjusted based on the sample WBC count; either via autosampler or open tube positions / antibodies: 4 μL – 100 μL, either single clone vials or cocktail vials

-Reagent capacity : system fluid: (DI H2 O) 9 L / waste: 9 L

lyse/buffers: 4 x 500 mL and 2 x 125 mL / antibody reagents: positions for up to 90 standard vials /peltier cooling: 2 C – 8 C for up to 30 Sysmex standard and cocktail vials

-Sample tube capacity : 50 primary sample tubes simultaneously via autosampler / up to 48 daughter tubes via 2 racks: 24-tube fixed-angle rack or 12- or 24-position swing-out rotor / compatible with Hettich Rotolavit II-S automated cell wash centrifuge for automated sample wash steps

-System performance accuracy :

sample:20 μL – 49 μL +/- 10% by volume

sample:50 μL – 100 μL +/- 5% by volume

reagent:4 μL – 19 μL +/- 20% by volume

reagent:20 μL – 100 μL +/- 7% by volume

lyse:450 μL – 2,000 μL +/- 3% by volume

precision:

sample:20 μL – 100 μL CV ≤ 5% by volume

reagent:4 μL – 19 μL CV ≤ 15% by volume

reagent:20 μL – 100 μL CV ≤ 5% by volume

lyse:450 μL – 2,000 μL CV ≤ 3% by volume

throughput:

48 tests/h, two-tube panel, lyse no-wash, includes 10 min stain incubation and 10 min lyse incubation

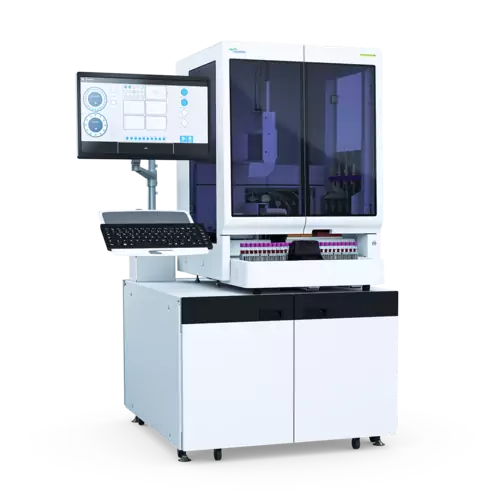

-Weight : 129 kg (258 lbs)

-Dimensions H x W x D : PS-10: 106.3 x 75.5 x 94 cm (41.8” x 29.7” x 37”) (excluding keyboard and touchscreen) / optional base: 70.6 x 100 x 114 cm (28” x 39” x 45”)

-Power requirements : 100 – 240 VAC +/- 10%, 50/60 Hz, 10 A

-Environment : operating temperature: 15°C – 35°C (59°F – 95°F) / operating relative humidity: 10% – 80% non-condensing / noise level: standby mode < 60 dB, run mode < 75 dB peak

Automate your sample preparation processes

The PS-10 automates antibody cocktailing and sample preparation using an onboard selection of antibody and lyse or fixation reagents. By automating many manual steps, it frees up the time of laboratory staff for other tasks.

Customise procedures to match your needs while ensuring traceability

Custom-built assays can be easily created by combining simple processing steps, including cell wash, to adapt to individual laboratory needs.

Compatible with antibody reagents from a variety of manufacturers, it can be programmed to create antibody cocktails or use single antibodies.

The information for reagents and procedures is stored for re-use – and easy traceability of data.

Maximise your workflow efficiency

By automating both the manual steps and documentation associated with sample preparation, the PS-10 reduces hands-on time, allowing laboratory staff to use that time to focus on other tasks.

Multiple design elements are incorporated to maximise workflow efficiency: from dual pipetting probes to multi-aliquoting for multi-tube panels.

For wash procedures, the daughter tube rotors can be easily transferred from the PS-10 to the Hettich Rotolavit II-S automated cell wash centrifuge, virtually eliminating daughter tube handling and human errors during these steps.

Flexibly standardise your preparation processes

The automated processing by nature eliminates operator-dependent variability, thus leading to an increased level of standardisation compared to manual preparation. Reduction of possible human errors at many steps adds a further level of confidence in the results.

Similar Products

You might also be interested in these products